ROLAIR 6820K17D 120V/230V Wheeled Electric Air Compressor – 6820K17D-0001

9999 in stock

$1,402.99 Original price was: $1,402.99.$1,332.99Current price is: $1,332.99.

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

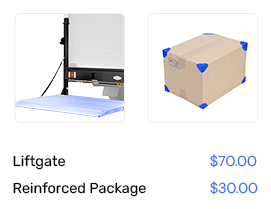

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

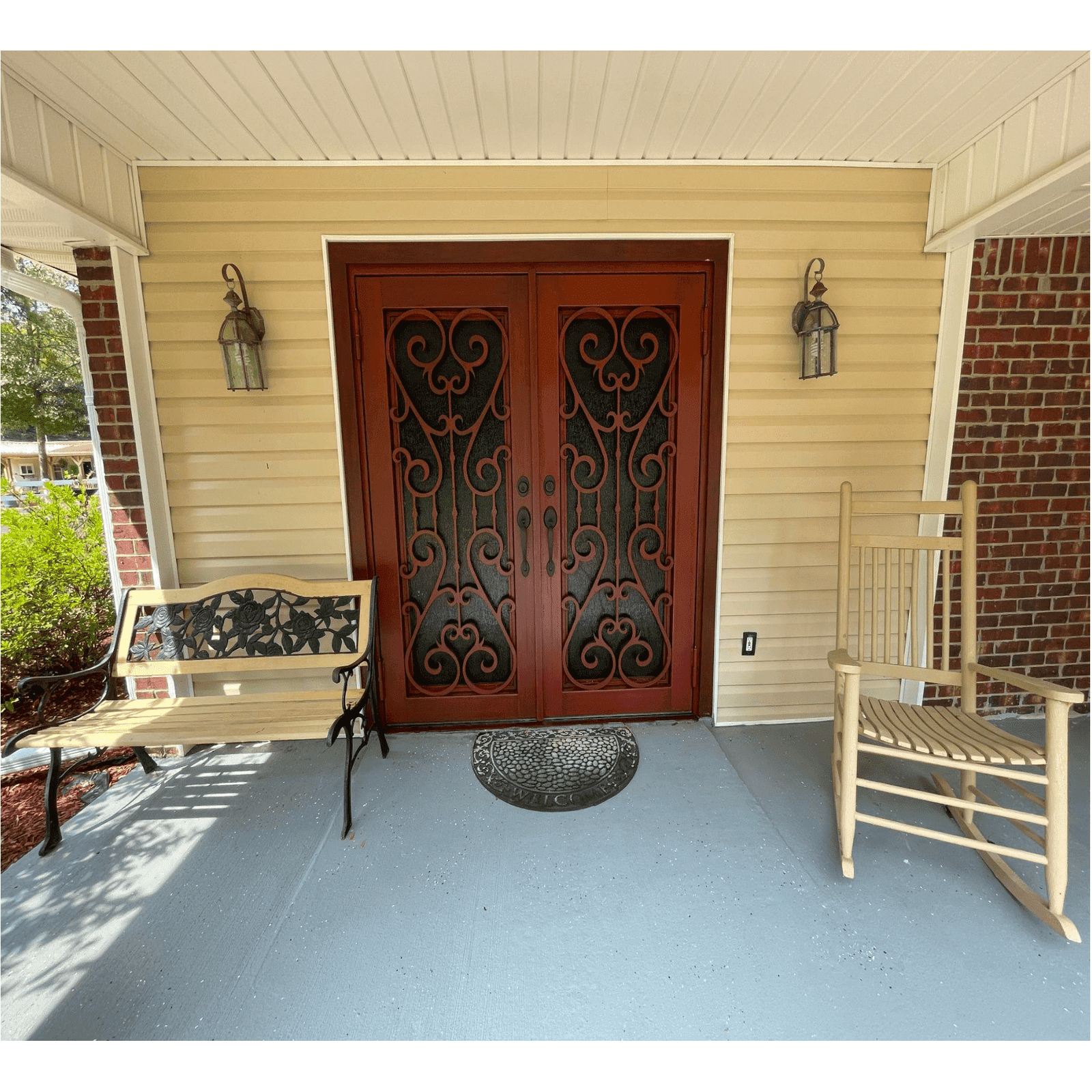

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

ROLAIR 6820K17D 120V/230V Wheeled Electric Air Compressor – 6820K17D-0001

Model 6820K17D includes a dual-control feature, which allows it to run start/stop or constant-speed operation. This model provides the most air available on a 110 Volt electric compressor, yet is equipped with a dual-voltage switch allowing you to run off 220 Volt when needed.

Specifications

| HORSE POWER | 2 HP |

|---|---|

| CFM DISPLACED | 12.5 CFM |

| CFM DELIVERED | 8.8 CFM 90 PSI |

| PUMP/MOTOR RPM | 1740 RPM |

| OVERLOAD PROTECTION | Yes (Manual Reset Standard) |

| LUBRICATION TYPE | Splash Lubrication |

| PUMP OIL CAPACITY | 34 oz. |

| REED VALVE SYSTEM | Yes (Standard) |

| NUMBER OF CYLINDERS | 2 |

| TANK CAPACITY | 9 Gallons |

| L X W X H | 46″x19″x28″ |

| DECIBEL RATING | Unavailable |

| SHIPPING WEIGHT | 185 lb. |

| SHIPPING DIMENSIONS (L X W X H) | 47″ x 22″ x 36″ |

What Our Experts Think

- Dual Voltage Capability (120V/230V) – Versatile power options for different job site requirements.

- Heavy-Duty Cast-Iron Pump – Ensures durability and long-term performance.

- Wheeled Design – Provides easy mobility for transport between work areas.

- High-Capacity Airflow – Supports multiple tools simultaneously for increased efficiency.

- Industrial-Grade Build – Ideal for workshops, contractors, and heavy-duty applications.

Q&A

Q: What is the ROLAIR 6820K17D?

A: The ROLAIR 6820K17D is a versatile, wheeled electric air compressor designed for professional and industrial applications. It operates on dual voltage (120V/230V) for flexible power options.

Q: What motor does it use?

A: It features a 1.5 HP, dual-voltage motor capable of running on 120V or 230V, making it suitable for different job site power requirements.

Q: What is the tank capacity and PSI rating?

A: The compressor comes with a 20-gallon horizontal air tank and delivers a maximum pressure of 135 PSI.

Q: What is the CFM output?

A: It provides 6.9 CFM at 90 PSI, ensuring steady airflow for pneumatic tools and job site applications.

Q: Is it portable?

A: Yes, it is designed with heavy-duty wheels and a sturdy handle, allowing for easy mobility in workshops and construction sites.

Maintenance Tips

- Drain Tank Daily – Prevent rust and moisture buildup by releasing condensation.

- Check & Change Oil – Regularly monitor and replace compressor oil for optimal performance.

- Inspect Air Filter – Clean or replace to maintain proper airflow and efficiency.

- Check for Leaks – Tighten all fittings and hoses to prevent air loss.

- Monitor Pressure Gauges – Ensure stable pressure levels and detect irregular fluctuations.

- Inspect Electrical Components – Check power connections, wiring, and motor for any signs of wear or damage.

- Lubricate Moving Parts – Keep belts and bearings properly lubricated to reduce wear and extend lifespan.

- Store in a Dry, Clean Area – Protect from moisture and debris to prevent corrosion and electrical issues.

Additional information

| GoogleProductCategory | 2015 |

|---|---|

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-06-03T16:45:15Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Hinkley Lighting Outdoor Danbury Aged Zinc Post Mount Light – 2537DZ

$439.00 -

Sale -5%

MotoTec Mud Monster 48V/12Ah 1000W Full Suspension Electric Go Kart MT-GK-Mud-1000w

$1,219.00Original price was: $1,219.00.$1,158.99Current price is: $1,158.99. This product has multiple variants. The options may be chosen on the product page -

Sale -5%

ScubaPro Seahawk II with AIR2 V GEN Scuba Diving BC/BCD – BCD320 02-SM

$999.00Original price was: $999.00.$949.99Current price is: $949.99. This product has multiple variants. The options may be chosen on the product page -

Hinkley Lighting Outdoor Plantation Copper Bronze Post Mount Light – 2227CB

$1,899.00

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet