Forney 270 MIG Welder – 319

9999 in stock

$3,199.99

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

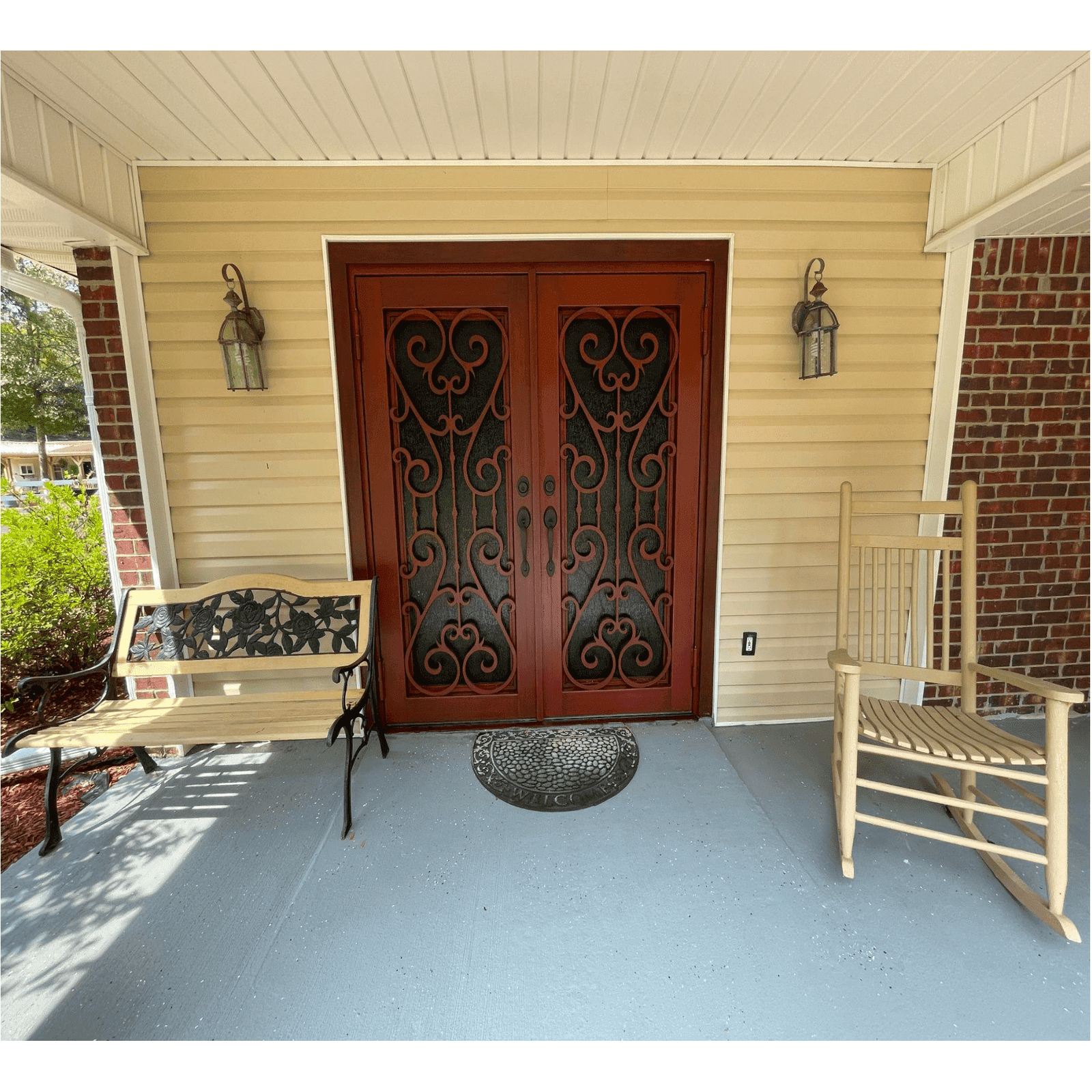

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

Forney 270 MIG Welder – 319

The Forney 270 MIG welder is a versatile machine for light industrial, repair shops, farms, automotive, and general fabrication. This machine is MIG ready with regulator and gas hose. The Forney 270 MIG offers quality features like spool gun capability, quick “Euro” style disconnect torch, MIG gun with 15′ lead, aluminum feed/drive system, multiple trigger modes, high output and duty cycle with a full size cabinet. The quality, performance, and value of this machine will impress.

Features Include

- Euro-connect MIG gun with Tweco compatible consumables

- Digital readout

- Multiple trigger modes for spot welding, 2T – for normal trigger pull on/off, and 4T – for sustained long welds

- Long 15′ (4.5m) MIG gun/torch

- Long 15′ (4.5m) power cord

- 15′ ground cable and clamp

- Spool Gun Ready

- Full-size machine with integrated casters and wheels

- Integrated cable wrap

- Aluminum wire feeder and drive system

- Quality and adaptable spool holder/retainer

- Standard U.S. gas hose set-up

- Flowmeter and gas hose included

- Quality metal cabinet with no assembly required, improved spool access and more space inside, and fold up door

- Full graphics box, quick-start guide, and owner’s manual

- Dimensions: 38″ x 14″ x 34″

- Weight: 240 lbs.

Specifications

- Input Power: 230V

- Maximum Output: 270 Amps

- Type: Transformer based, multi-step

- Processes: MIG (GMAW), Flux Cored (FCAW)

- Acceptable Spool Sizes: 4″, 8″ & 12″

- Acceptable Wire Diameters: Up to .045″

What Our Experts Think

- Powerful Performance: Delivers up to 270 amps, perfect for heavy-duty welding projects.

- Multi-Process Capabilities: Supports MIG, Flux-Core, and Stick welding for versatility.

- User-Friendly Controls: Easy-to-adjust settings for precision welding across various materials.

- Durable & Reliable: Built with high-quality components for long-lasting performance.

- Spool Gun Ready: Compatible with spool guns for effortless aluminum welding.

Q&A

Q: What is the Forney 270 MIG Welder – 319?

A: A powerful, versatile MIG welder designed for industrial and heavy-duty applications, offering precision and reliability.

Q: What materials can it weld?

A: Ideal for mild steel, stainless steel, and aluminum (with the appropriate spool gun).

Q: What is the amperage range?

A: 30–270A, providing flexibility for various welding thicknesses and materials.

Q: Does it support multiple welding processes?

A: Yes, it supports MIG, Flux-Core, and Spool Gun welding.

Q: What is the duty cycle?

A: 60% at 200A, ensuring extended welding performance without frequent cooldowns.

Q: Is it easy to use?

A: Yes, it features intuitive controls, a digital display, and adjustable settings for precision welding.

Q: What power input does it require?

A: Runs on 230V, making it suitable for industrial and shop use.

Q: Does it include a warranty?

A: Yes, Forney offers a warranty for added peace of mind—check the manufacturer’s details for specifics.

Maintenance Tips

- Inspect Cables & Connections: Regularly check for loose, frayed, or damaged wires to ensure safe operation.

- Clean Drive Rollers & Wire Feed System: Remove dust and debris to maintain smooth wire feeding and prevent jams.

- Monitor & Replace Contact Tips & Nozzles: Worn tips affect arc stability—replace them as needed for consistent welds.

- Check Ground Clamp: Ensure a secure, clean ground connection to prevent erratic arc behavior.

- Inspect Gas Flow & Hoses: Check for leaks and maintain proper shielding gas flow for high-quality welds.

- Follow Duty Cycle Limits: Prevent overheating by operating within the recommended duty cycle.

- Keep Ventilation Openings Clear: Clean dust and debris from cooling vents to maintain proper airflow.

- Store in a Dry, Clean Area: Protect from moisture and contaminants to extend the lifespan of the welder.

- Perform Routine Maintenance: Regularly inspect fans, wire drive mechanisms, and internal components for wear or buildup.

Additional information

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

|---|---|

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-06-01T01:20:43Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Sale 9%

Forney 140 MP Welder, “3-in-1” Multiple Welding Processes – 322

$856.39Original price was: $856.39.$779.99Current price is: $779.99. -

Sale 9%

Forney Easy Weld 100 ST Stick Machine – 298

$349.99Original price was: $349.99.$319.99Current price is: $319.99. -

Sale 9%

Forney 140 MIG Welder -309

$799.99Original price was: $799.99.$729.99Current price is: $729.99. -

Forney 220 ST PRO Welder – 430

$1,799.99

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet