Forney 220 Multi-Process (MP) Welder – 410

9999 in stock

$1,999.99

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

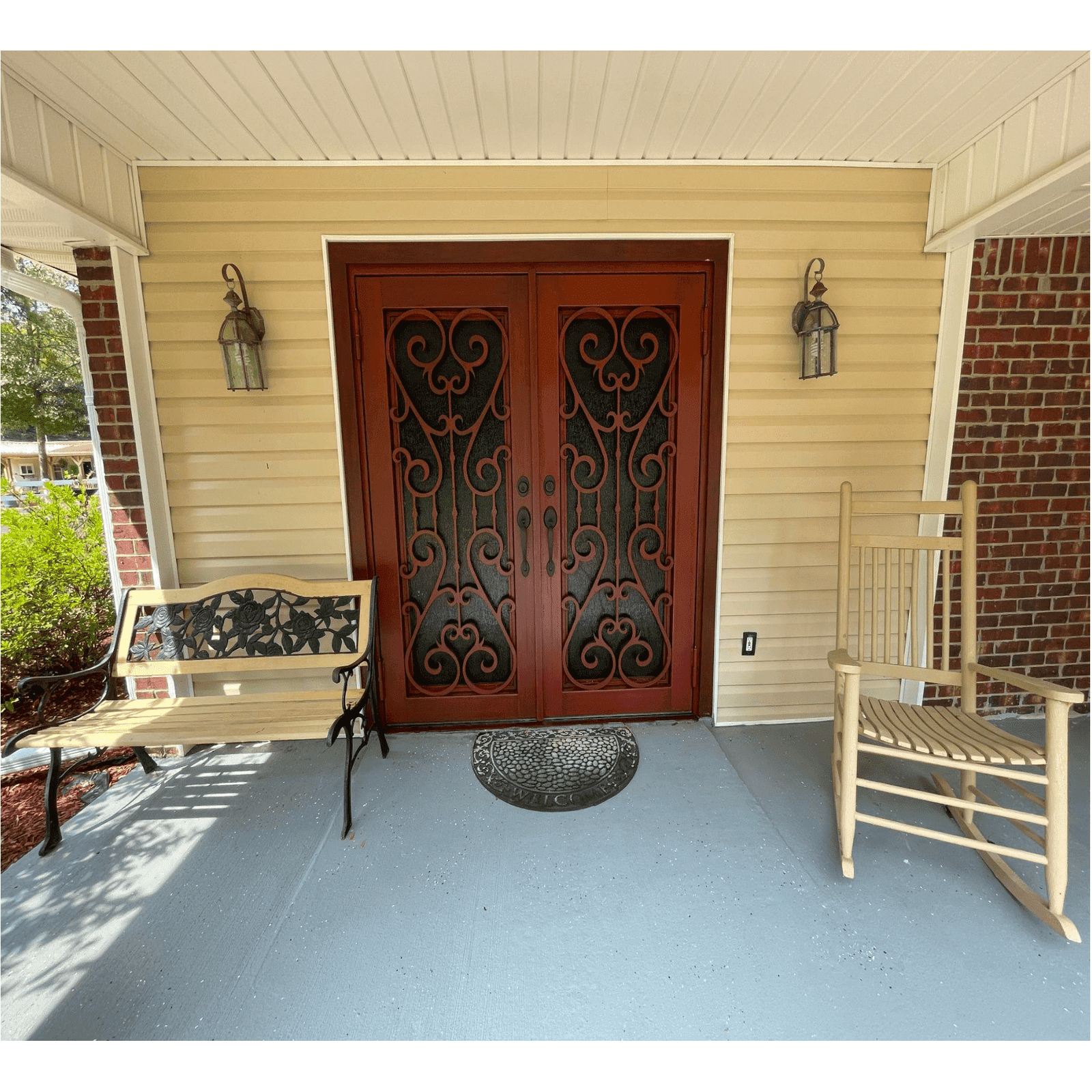

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

Forney 220 Multi-Process (MP) Welder – 410

Forney 220 Multi-Process (MP) Welder

His preferred field of expertise is routine maintenance welding and quick on-site troubleshooting. In fact, thanks to its small size and limited weight for a semiautomatic welding machine, it can be taken anywhere. It is suitable for gas-free flux-cored wire or gas conventional wire (MIG) or conventional rod (ARC) welding.

???????????????????????????? ????????????: There is a lot of use of this Forney 220 Multi-Process (MP) Weldersuch as on steel, stainless steel, cast iron, and aluminum. Ideal for anything from do-it-yourself projects to light industrial work, this powerful welding machine features.

???????????????????????????????????????? ????????????????????????????: There are lots of unique features with this product like All-Metal Drive System, Multi-Process, Auto Torch Detect, Digital Displays, and Dual-Voltage which makes the best product for Welder.

????????????????????????????????: There is a 3-year warranty on this product. and the machine is rugged and technologically advanced with a digital display, all-metal drive system.

????????????????-????????????????????????????: Forney’s 220 Multi-Process welders are equipped with dual-voltage 120V/230V input power and adapter.

???????????????? ???????? ????????????: Very easy to use this product with any complexity. The proper switch allows you to change the process quickly.

???????????????? ???????? ????????????????????: Lightweight easily carried to any, Maintenance, Repair, Metal Fabrication, and Hobbyist project.

???????????????? ???????????????????????????? ????????????????????????????: Best ingredients are used to produce this product for long-lasting use.

Features

- All-Metal Drive System

- Auto Torch Detect

- Digital Displays

- Multi-Process

- Dual-Voltage

???????????????????????????????? ????????????????????????????????????????????

- 12.5’ (3.81 m) 200 AMP PRO-Grip MIG Gun

- 15’ (4.57 m) Ground Clamp with Cable

- 15’ (4.57 m) Electrode Holder with Cable

- 15’ (4.57 m) Input Power Cable

- Flowgauge with Hose

- Extra Contact Tips

Specification

| Processes: | GMAW (MIG) FCAW (Flux-Cored) SMAW (Stick) GTAW- DC (TIG) |

|---|---|

| Output Power: |

MIG: 120V: 35% @ 90 AMP 230V: 40% @ 200 AMP Stick: 120V: 32% @ 80 AMP 230V: 40% @ 200 AMP TIG: 120V: 35% @ 110 AMP 230V: 40% @ 200 AMP |

| Input Power: | 120V @ 21.4 AMP 230V @ 38 AMP |

| Welding Capacity: | Up to 1/2 inch |

| Wire/Electrode Diameters: | .024” (0.6 mm) to .035” (0.9 mm) |

| Unit Weight of Welder Out of Display Box: | 51 lbs. (23.18 kg) |

| Unit Dimensions of Welder Out of Display Box: | H: 15.5” (393.7 mm) L: 23.25” (263.53 mm) W: 10.375” (590.55 mm) |

What Our Experts Think

- Versatile Welding: Supports Stick and TIG welding for a range of applications.

- Powerful Performance: Delivers up to 220 amps, ideal for professional and heavy-duty jobs.

- Dual Voltage Compatibility: Operates on both 120V and 240V for maximum flexibility.

- Lightweight & Portable: Compact design with a sturdy handle for easy transport.

- Easy-to-Use Controls: Simple setup with adjustable settings for precision welding.

Q&A

Q: What is the Forney 220 MP Welder – 410?

A: A multi-process welder that supports MIG, Stick, and DC TIG welding for versatility in various applications.

Q: What welding processes does it support?

A: MIG (GMAW), Stick (SMAW), and DC TIG (GTAW) welding.

Q: What is the amperage range?

A: 120V: 10–140A, 240V: 10–220A, offering flexibility for different material thicknesses.

Q: What power input does it require?

A: Dual-voltage (120V/240V) capability for home and industrial use.

Q: What is the duty cycle?

A: 60% at 220A (240V) for extended welding time without overheating.

Q: Can it weld aluminum?

A: Yes, but requires a spool gun for MIG aluminum welding (sold separately).

Q: Does it have a digital display?

A: Yes, an easy-to-read digital display for precise adjustments.

Q: Is it portable?

A: Yes, lightweight and compact with a durable handle for easy transport.

Q: Does it come with a warranty?

A: Yes, Forney provides a manufacturer’s warranty—check specifics for details.

Maintenance Tips

- Inspect Cables & Connections: Check for loose, frayed, or damaged wires to ensure safe and reliable operation.

- Clean Drive Rollers & Wire Feed System: Remove dust and debris for smooth wire feeding and consistent weld quality.

- Monitor & Replace Contact Tips & Nozzles: Worn tips affect arc stability—replace them regularly for optimal performance.

- Check Ground Clamp: Ensure a secure, clean connection to prevent erratic arc behavior.

- Inspect Gas Flow & Hoses: Look for leaks and maintain proper shielding gas flow for MIG and TIG welding.

- Follow Duty Cycle Limits: Prevent overheating by adhering to the recommended duty cycle.

- Keep Ventilation Openings Clear: Clean dust and debris from cooling vents to ensure proper airflow and cooling.

- Store in a Dry, Clean Area: Protect from moisture and contaminants to extend machine life.

- Perform Routine Maintenance: Regularly inspect fans, wire drive mechanisms, and internal components for wear or buildup.

Additional information

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

|---|---|

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-06-01T01:19:30Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Sale 8%

Forney 100ST Welder Start-Up Kit – 29801

$399.99Original price was: $399.99.$369.99Current price is: $369.99. -

Forney 220 AC/DC TIG Welder Amptrol Package – 421

$2,399.99 -

Sale 39%

Forney Easy Weld 140 MP Machine – 271

$659.99Original price was: $659.99.$399.99Current price is: $399.99. -

Forney 700 P Plasma Cutter – 303

$1,599.00

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet