Current Tools Right Angle Twin Yoke 24in. Diameter Sheave – Reconditioned – Current Tools 4424

9999 in stock

$672.00 Original price was: $672.00.$471.00Current price is: $471.00.

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

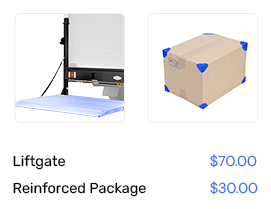

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

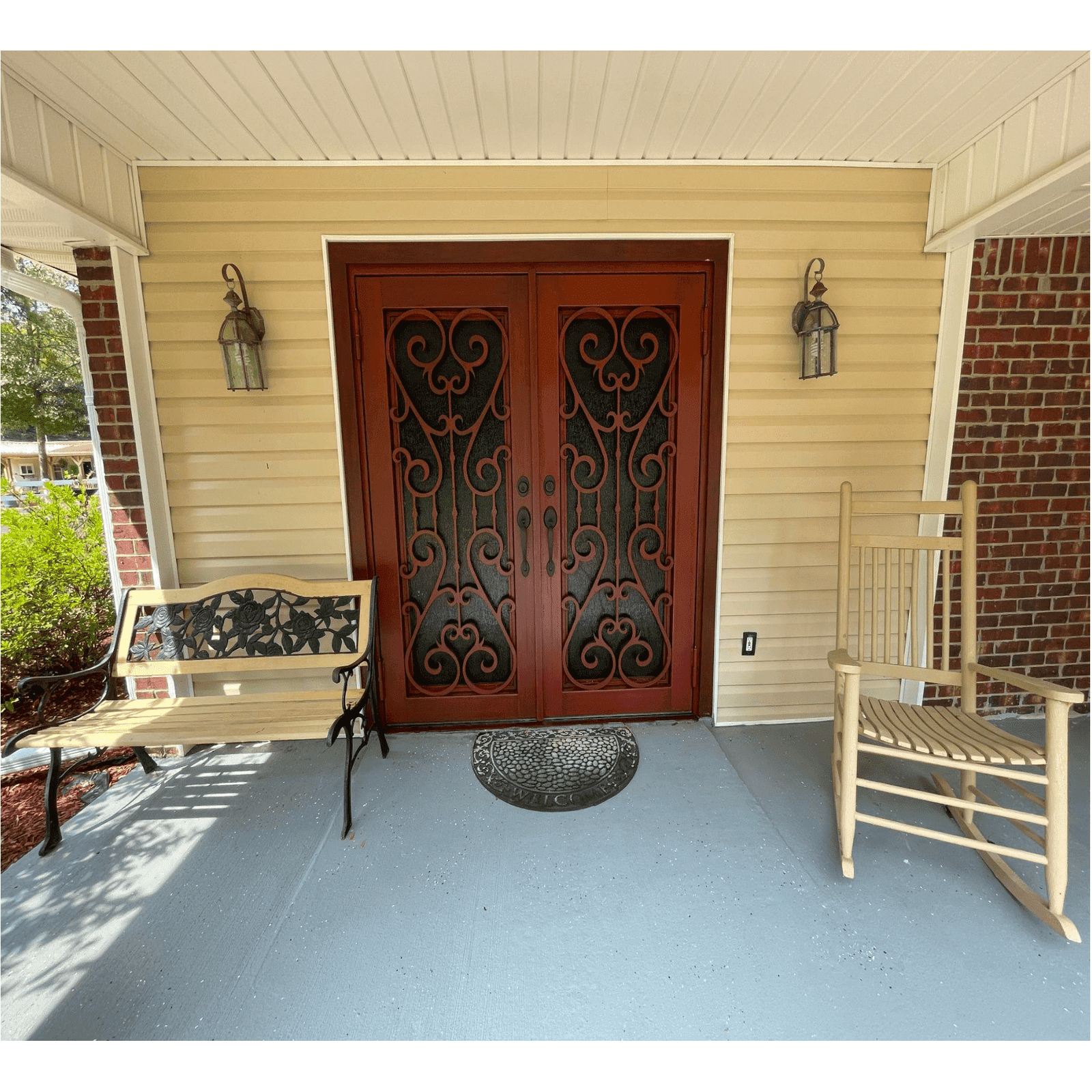

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

Current Tools Right Angle Twin Yoke 24in. Diameter Sheave – Reconditioned – Current Tools 4424

24” diameter Sheave

4,000 lbs. Capacity

Forged steel hooks with 1’’ opening

Yokes rotate independently for various setups

Welded steel yoke frames

5″ wide aluminum sheave with self-lubricating bearings

Made In the USA

What our Experts Think

-

High-Capacity Cable Handling: The Current Tools 4424 Right Angle Twin Yoke Sheave is designed for efficient cable pulling with a 24″ diameter for smooth operation.

-

Reconditioned for Value: Fully inspected and restored for like-new performance, offering cost savings without sacrificing reliability.

-

Heavy-Duty Construction: Built with durable, high-strength materials, ensuring long-lasting performance in demanding job site conditions.

-

Optimized for Right-Angle Applications: The twin yoke design allows for secure, precise cable routing, reducing friction and wear.

-

High Load Capacity: Engineered to handle heavy cable loads, making it ideal for industrial and commercial use.

Q&A

Q: What is the Current Tools 4424 Right Angle Twin Yoke 24″ Diameter Sheave?

A: The Current Tools 4424 is a reconditioned right-angle twin yoke sheave with a 24-inch diameter, designed for guiding and supporting cables during pulling applications.

Q: What is it used for?

A: It is used in cable pulling operations to ensure smooth movement and reduce friction when installing electrical wiring in industrial and commercial projects.

Q: What does “Reconditioned” mean?

A: “Reconditioned” means the tool has been inspected, tested, and restored to full working condition, with possible minor cosmetic imperfections.

Maintenance Tips

-

Inspect for Damage – Check for cracks, bends, or wear on the sheave and yoke.

-

Keep Clean & Free of Debris – Wipe down regularly to prevent dirt buildup, which could affect performance.

-

Lubricate Moving Parts – Apply manufacturer-recommended lubrication to reduce friction.

-

Check Mounting Hardware – Ensure bolts and fasteners are secure to maintain stability.

-

Monitor for Uneven Wear – Check the sheave for uneven wear, which could indicate misalignment.

-

Ensure Proper Alignment – Align the sheave properly with the application to avoid unnecessary strain.

-

Avoid Overloading – Operate within the rated capacity to prevent excessive wear or damage.

-

Store in a Dry Area – Keep the sheave in a moisture-free environment to avoid rust and corrosion.

-

Inspect for Loose Components – Tighten any loose parts before use.

-

Follow Manufacturer’s Guidelines – Perform routine inspections and follow the maintenance schedule for optimal longevity.

Additional information

| Weight | 39.8 kg |

|---|---|

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-05-18T16:17:50Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Canon RF 1.4x Extender – 795100

$499.99 -

Sale 30%

Current Tools BSD95 Convertible Bandsaw 1/2HP 8×10 in. – Reconditioned – Current Tools BSD95

$6,123.00Original price was: $6,123.00.$4,286.00Current price is: $4,286.00. -

Sale 15%

Current Tools Standard Hydraulic Knockout Set – New Surplus – Current Tools 152

$1,087.00Original price was: $1,087.00.$924.00Current price is: $924.00. -

Sale 5%

Sony Camera Sony FE 2.0x Teleconverter – 4638946389

$549.99Original price was: $549.99.$522.99Current price is: $522.99.

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet