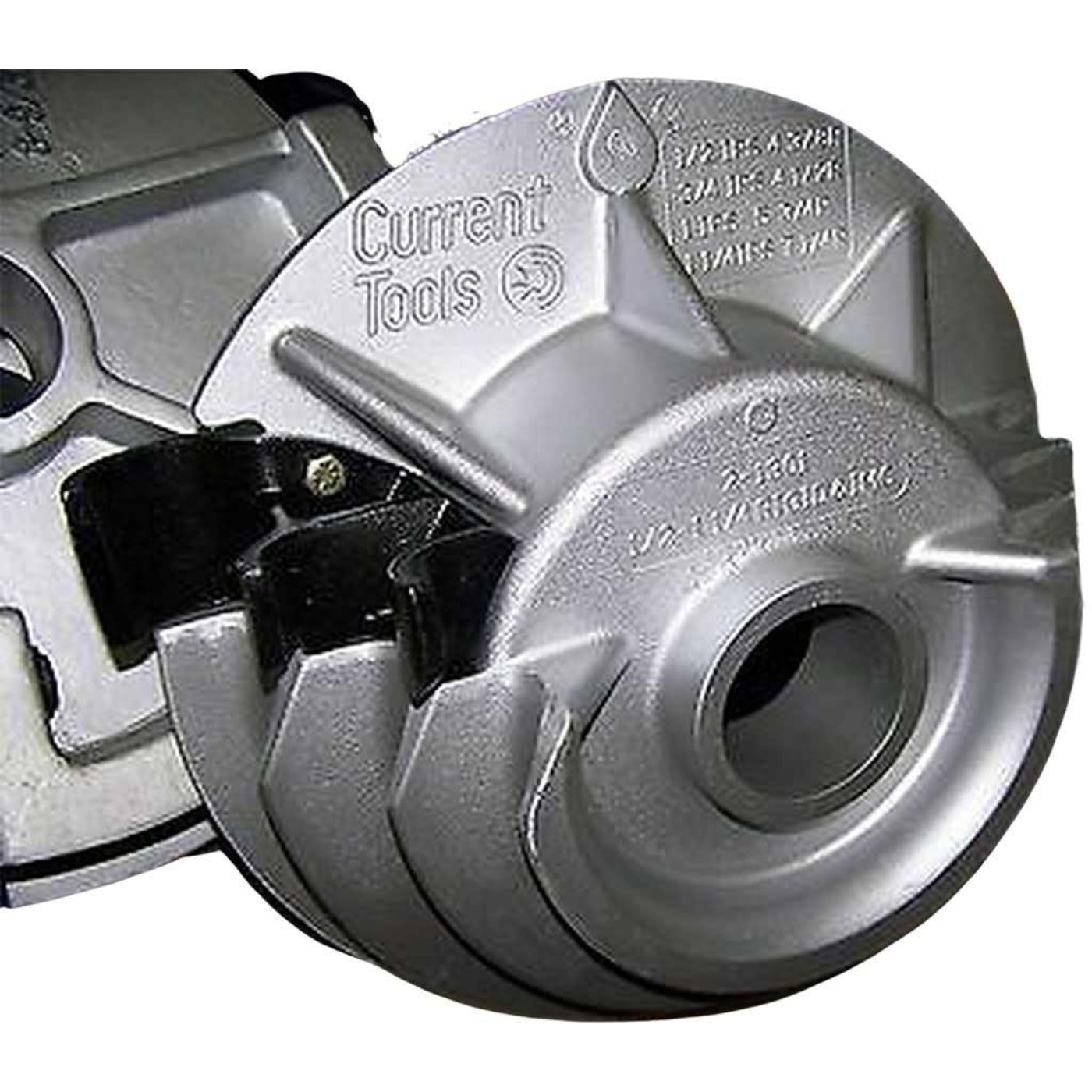

Current Tools Bending Shoe for 1-1/2in EMT Conduit- Reconditioned – Current Tools 2-1601

9999 in stock

$835.00 Original price was: $835.00.$585.00Current price is: $585.00.

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

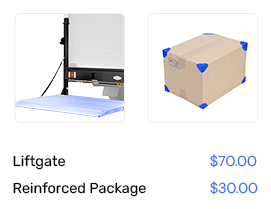

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

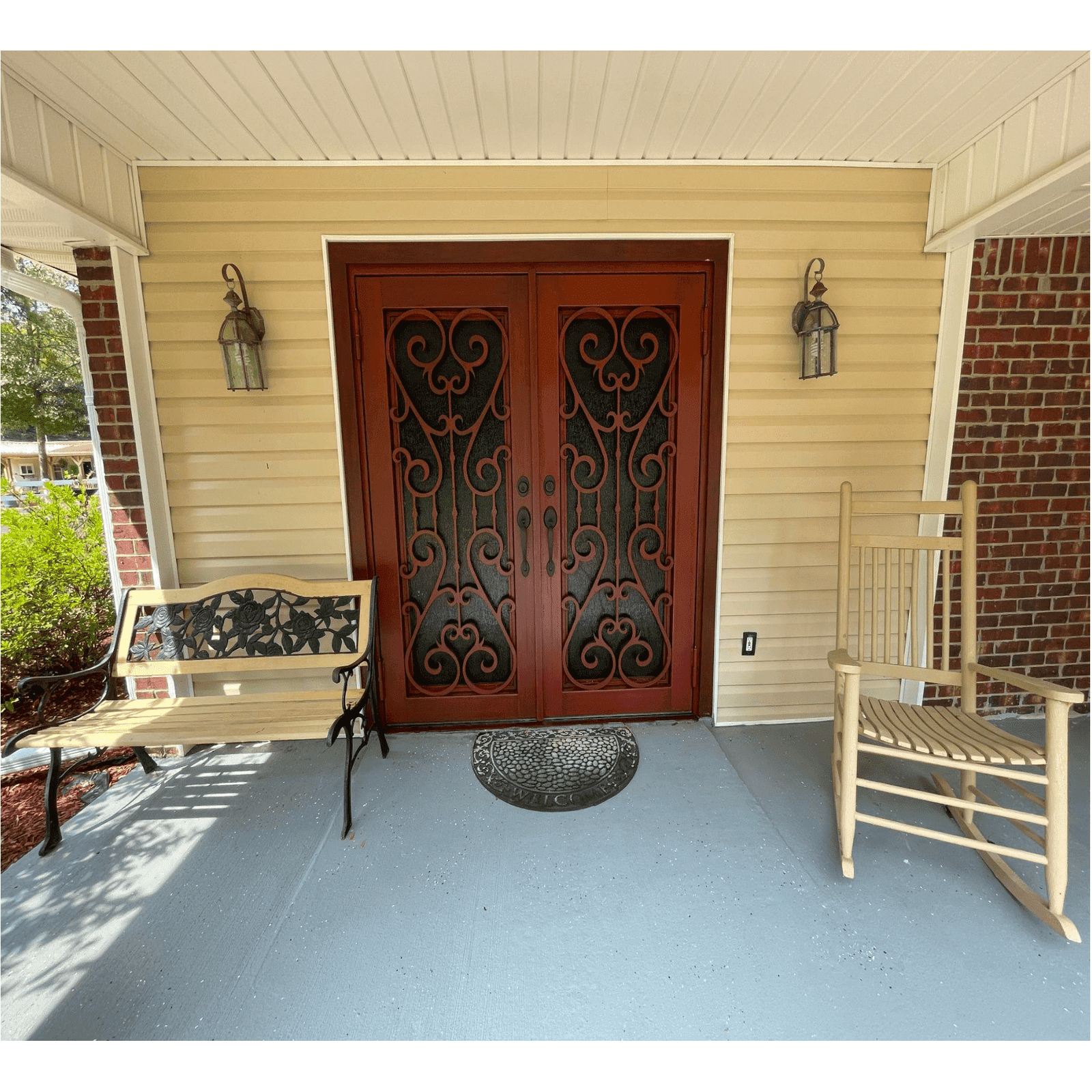

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

Current Tools Bending Shoe for 1-1/2in EMT Conduit- Reconditioned – Current Tools 2-1601

Current Tools 2-1601 Bending Shoe for 1-1/2in EMT Conduit – Reconditioned

The Current Tools 2-1601 Bending Shoe is a high-quality, reconditioned component designed for bending 1-1/2-inch EMT conduit with precision and ease. This durable shoe is essential for electricians and contractors needing accurate conduit bends in industrial and commercial applications.

(1) Single shoe

EMT Shoe

1-1/2″

For Current 77 Bender or Greenlee 555

Features

- Designed for 1-1/2″ EMT conduit – Ensures precise and consistent bends

- Heavy-duty construction – Built for durability and long-lasting use

- Compatible with Current Tools bending systems – Ensures seamless operation

- Reconditioned – Fully inspected, tested, and restored for reliable performance

What our Experts Think

-

Precision Conduit Bending: The Current Tools 2-1601 Bending Shoe ensures smooth, accurate bends for 1-1/2″ EMT conduit.

-

Reconditioned for Value: Fully inspected and restored for like-new performance at a budget-friendly price.

-

Durable Construction: Built from high-strength materials for long-lasting reliability on the job site.

-

Seamless Compatibility: Works with Current Tools mechanical and hydraulic benders for efficient bending.

-

Optimized for Efficiency: Reduces material waste and ensures consistent, professional results.

Q&A

Q: What is the Current Tools 2-1601 Bending Shoe?

A: The Current Tools 2-1601 is a reconditioned bending shoe designed for bending 1-1/2″ EMT conduit with precision and ease.

Q: What is it used for?

A: It is used with conduit benders to create smooth, accurate bends in 1-1/2″ electrical metal tubing (EMT) for electrical installations.

Q: What does “Reconditioned” mean?

A: “Reconditioned” means the tool has been inspected, tested, and restored to full working condition, though it may have minor cosmetic imperfections.

Maintenance Tips

-

Inspect for Wear – Check for cracks, dents, or deformations before each use.

-

Keep Clean & Free of Debris – Wipe down after use to prevent buildup that could affect performance.

-

Lubricate Contact Points – Apply a light coat of lubricant to reduce friction and extend lifespan.

-

Ensure Proper Alignment – Position conduit correctly to avoid misbends or tool damage.

-

Avoid Overloading – Stay within the tool’s rated capacity to prevent stress or breakage.

-

Store in a Dry Area – Protect from moisture to prevent rust and corrosion.

-

Use with Compatible Benders – Ensure proper fit with your hydraulic or mechanical bender.

-

Check Fasteners & Bolts – Tighten any loose components to maintain stability.

-

Follow Manufacturer’s Guidelines – Adhere to proper bending techniques for precise results.

-

Schedule Routine Inspections – Regularly assess for wear and replace if necessary.

Additional information

| Weight | 25 kg |

|---|---|

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-05-18T16:17:48Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Sale 30%

Current Tools Rigid & IMC Bending Shoe – Reconditioned – Current Tools 2-1301

$903.00Original price was: $903.00.$632.00Current price is: $632.00. -

Sale 15%

Current Tools 36″ Radius Sheave – New Surplus – Current Tools 9236

$1,323.37Original price was: $1,323.37.$1,124.86Current price is: $1,124.86. -

Sale 34%

Harrington UBC100 Universal Beam Clamp 10 Ton – Reconditioned – UBC100

$542.65Original price was: $542.65.$356.90Current price is: $356.90. -

Sale 5%

Sony Camera Sony FE 85mm F1.8 – 143041

$599.99Original price was: $599.99.$569.99Current price is: $569.99.

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet