Atlas Copco 5HP, 16.5 CFM, 53 Gallon G4 Rotary Screw Air Compressor 208-230/460V -8152103795

19998 in stock

$6,653.00 – $6,728.00Price range: $6,653.00 through $6,728.00

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

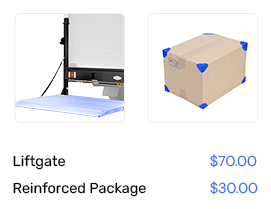

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

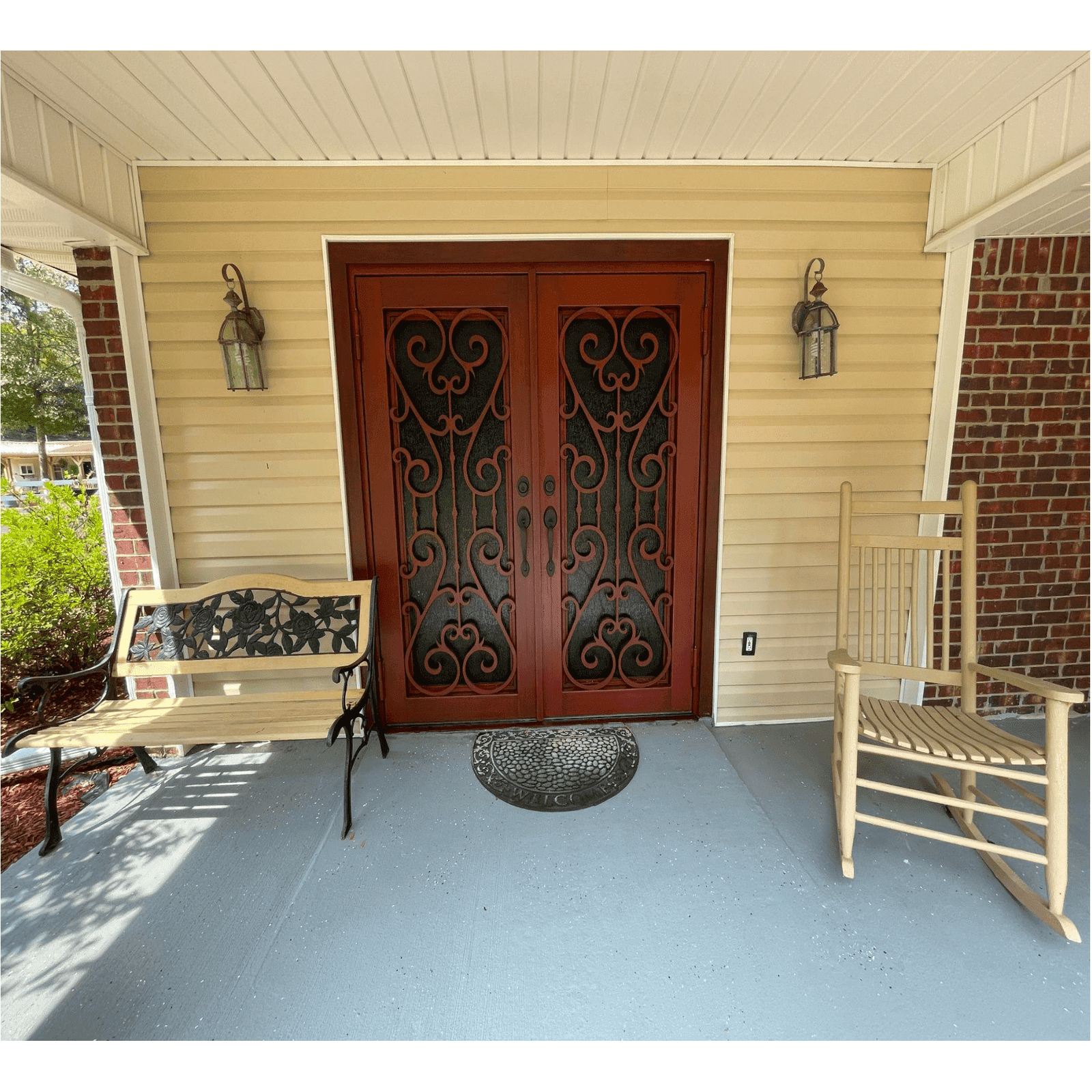

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

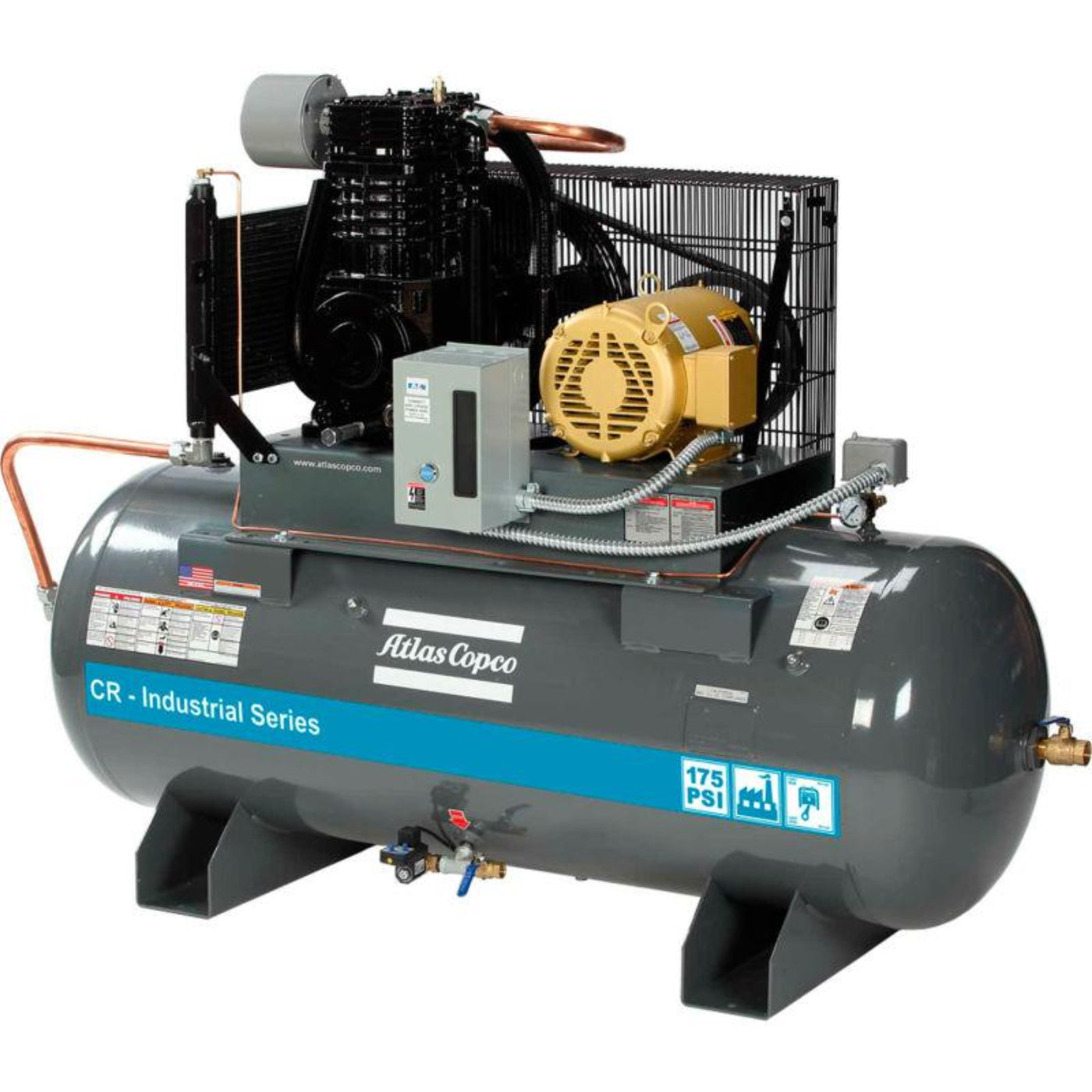

Atlas Copco 5HP, 16.5 CFM, 53 Gallon G4 Rotary Screw Air Compressor 208-230/460V -8152103795

Introducing our 4 kW screw air compressor, a robust and efficient addition to your operations. Its higher efficiency V-belt system saves up to 3% in energy costs over time. Easy plug-and-play installation, quiet at 62 dB, and featuring an electro-pneumatic inlet valve for stability and longevity. Unlike piston compressors, screws operate smoothly at high speeds with compact dimensions. Ideal for continuous, workplace, and industrial use, with options for oil-free or oil-injected versions, and fixed or variable speed drive operation. Elevate your efficiency with the G4 screw air compressor.

Product Image for Reference Only. Actual Product May Vary.

Specification

| Model | G4-145T AP 208-230/460, 53 gallon |

|---|---|

| Model Number | 8152103795 |

| Category | Rotary Screw Air Compressor |

| Product Range | G4 |

| Tank Capacity (Gallons) | 53 |

| CFM (Cubic Feet/Minute) | 16.5 |

| HP (Horse Power) | 5 |

| Voltage | 208-230/460 |

| Phase |

What Our Experts Think

- Reliable 5HP Motor – Delivers 16.5 CFM at 150 PSI, ideal for small to medium-sized operations with moderate airflow requirements.

- Rotary Screw Technology – Ensures smooth, continuous operation with minimal maintenance and enhanced longevity.

- 53-Gallon Tank – Provides adequate storage, reducing cycling and ensuring a steady supply of compressed air.

- Energy-Efficient – Operates on 208-230/460V three-phase power, optimizing energy consumption for cost-effective operation.

- Compact & Quiet – Space-saving design with low noise output, making it ideal for smaller workspaces or quieter environments.

- Durable & Reliable – Built to withstand demanding conditions, ensuring consistent performance over time.

Q&A

Q: What industries benefit from this compressor?

A: Ideal for light industrial applications, such as automotive repair shops, workshops, and small manufacturing operations that require reliable air compression.

Q: How does the rotary screw design improve efficiency?

A: The rotary screw mechanism ensures smooth, continuous airflow with minimal pulsation, reducing energy consumption and wear compared to piston compressors.

Q: What are the voltage requirements?

A: This model operates on 208-230V and 460V three-phase power, making it versatile for different industrial settings.

Q: What maintenance is required?

A: Regular maintenance includes oil changes, air filter replacement, and inspection of components for optimal performance and longevity.

Q: How does the 53-gallon tank enhance performance?

A: The 53-gallon tank provides a steady air supply, reducing the need for frequent cycling and ensuring continuous operation.

Maintenance Tips

- Check and Change Oil – Regularly monitor oil levels and replace according to manufacturer guidelines to ensure optimal lubrication and performance.

- Inspect and Replace Air Filters – Clean or replace air filters every 2,000–4,000 hours to maintain efficient airflow and prevent contaminants from entering the system.

- Drain Moisture from the Tank – Drain the 53-gallon tank regularly to prevent water buildup, rust, and corrosion in the compressed air system.

- Monitor Belt Tension – Inspect the drive belts and adjust or replace them as necessary to prevent slippage and maintain efficiency.

- Clean the Aftercooler – Periodically clean the aftercooler to prevent dust buildup and ensure optimal cooling performance.

- Check for Air Leaks – Inspect the system for leaks and seal any found to improve efficiency and reduce energy costs.

Additional information

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

|---|---|

| Liftgate Service | No, Yes (+$75.00) |

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-05-18T16:40:45Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Atlas Copco 25HP, 99 CFM, G18 Rotary Screw Air Compressor 208-230/460V – 8153335795

$9,509.00 – $9,584.00Price range: $9,509.00 through $9,584.00 This product has multiple variants. The options may be chosen on the product page -

Atlas Copco 10HP, 34.1 CFM, G7 Rotary Screw Air Compressor 208-230/460V – 8152103707

$9,509.00 – $9,584.00Price range: $9,509.00 through $9,584.00 This product has multiple variants. The options may be chosen on the product page -

Atlas Copco 10HP, 36 CFM, 120 Gallon CR Industrial Series Duplex TEFC/NEMA4 Cast Iron Piston Air Compressor 460V 1PH – 2020041905

$12,879.00 – $12,954.00Price range: $12,879.00 through $12,954.00 This product has multiple variants. The options may be chosen on the product page -

Atlas Copco 5HP, 16.5 CFM, 53 Gallon G4 Rotary Screw Air Compressor 208-230/460V -8152103841

$9,329.00 – $9,404.00Price range: $9,329.00 through $9,404.00 This product has multiple variants. The options may be chosen on the product page

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet