Atlas Copco 7.5HP, 18 CFM, 80 Gallon CR Industrial Series Piston Air Compressor 230V 3PH – 2020041517

9999 in stock

$5,751.00 Original price was: $5,751.00.$4,957.00Current price is: $4,957.00.

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

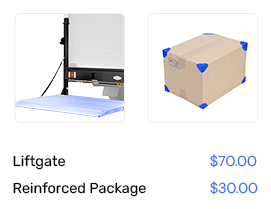

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

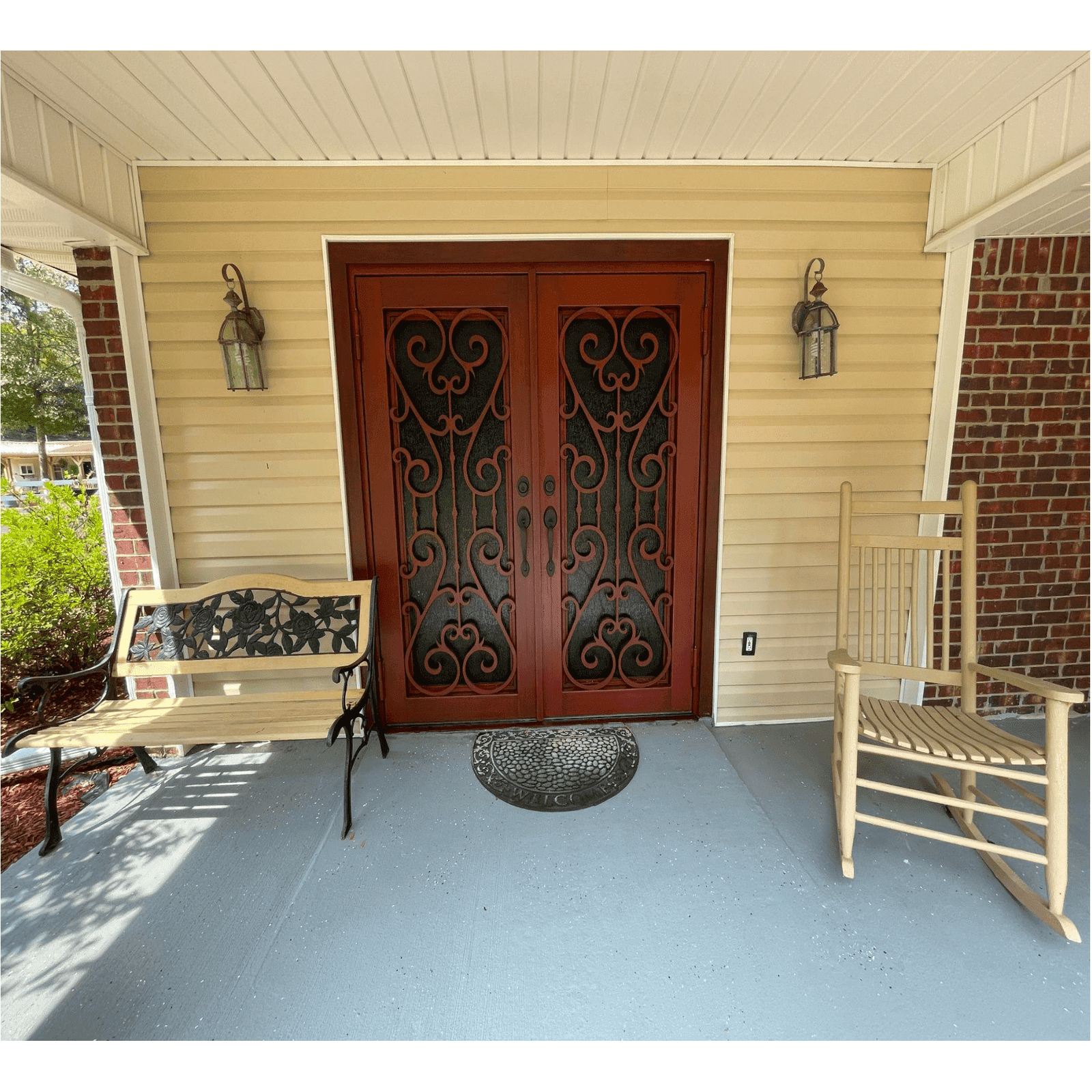

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

Atlas Copco 7.5HP, 18 CFM, 80 Gallon CR Industrial Series Piston Air Compressor 230V 3PH – 2020041517

Atlas Copco CR7.5-CRS1-80V 230/3 Piston Air Compressor

Introducing the Atlas Copco CR7.5-CRS1-80V 230/3 Air Compressor, the ultimate customizable compressor for contractors, professionals, and industry experts. This robust machine is constructed with heavy-duty cast iron and precision engineering, ensuring a consistent air pressure of up to 175 psig. Rest assured, we’ve got you covered with our warranty packages, including an impressive 5-year extended option. So go ahead and personalize it with our configurable options, and find the ideal fit for all your compressed air requirements. Trust the CR Atlas Copco Cast Iron Piston Compressor for exceptional performance and unwavering reliability.

Specifications

| Model | CR7.5-CRS1-80V 230/3 |

|---|---|

| Model Number | 2020041517 |

| Category | Piston Air Compressor |

| Product Range | CR Industrial Series |

| Tank Capacity (Gallons) | 80 |

| CFM (Cubic Feet/Minute) | 18 |

| HP (Horse Power) | 7.5 |

| Voltage | 230 |

| Phase | 3 |

What our Expect Think

- 7.5HP Motor with 18 CFM Output: Delivers a strong and steady flow of compressed air, ideal for medium-duty industrial tasks and continuous operations.

- 80-Gallon Tank: Provides ample storage for compressed air, reducing frequent cycling and enhancing overall efficiency during use.

- 230V 3-Phase Power: Perfect for industrial and commercial settings, offering stable and efficient power for high-demand applications.

- Industrial-Grade Piston Design: Built to last with rugged construction, designed to handle demanding environments while providing reliable performance.

- Low Maintenance: Engineered for easy service, minimizing downtime and extending the lifespan of your compressor, reducing long-term operational costs.

Q&A

Q: What is the primary use of the Atlas Copco CR Industrial Series 7.5HP air compressor?

A: This air compressor is ideal for medium to large industrial applications that require continuous and reliable compressed air for powering pneumatic tools, equipment, or other machinery.

Q: What are the key specifications of this compressor?

A: The compressor features a 7.5HP motor, delivering 18 CFM, with an 80-gallon tank. It operates on 230V, 3-phase power, making it suitable for industrial facilities with these power configurations.

Q: How does the CR Industrial Series differ from other models?

A: The CR Industrial Series is designed for high performance and long-lasting reliability. It is built with a piston-type compressor for increased efficiency and durability in demanding industrial environments.

Q: Is this air compressor suitable for continuous use?

A: Yes, the 7.5HP, 18 CFM configuration of this compressor is designed for continuous operation, making it ideal for businesses that rely on steady compressed air supply throughout the workday.

Q: What is the voltage and phase of this air compressor?

A: This compressor runs on 230V, 3-phase power, which is commonly used in industrial settings for higher efficiency and reliable performance.

Q: How does this air compressor compare to other options in its class?

A: The 7.5HP, 18 CFM, 80 Gallon configuration provides the perfect balance of power, capacity, and reliability for businesses needing a durable compressor that can handle demanding tasks.

Maintenance Tips

- Regularly Check Oil Level – Keep the oil level at the recommended level and change it according to the manufacturer’s guidelines to ensure smooth performance and prevent damage.

- Clean the Air Filter – Clean or replace the air filter every 6 months to prevent dust and debris from entering the compressor and affecting its efficiency.

- Drain the Air Tank – Drain the tank daily to remove moisture buildup, which can cause corrosion and affect compressor efficiency.

- Inspect Belts and Pulleys – Periodically check belts and pulleys for wear or damage, and replace them if necessary to avoid system failures.

- Inspect Electrical Connections – Ensure all electrical connections are tight and free of corrosion, especially on the motor and control panel.

- Lubricate Moving Parts – Lubricate the compressor’s moving parts, such as pistons, valves, and bearings, to keep them in optimal condition.

- Check Pressure Relief Valve – Test the pressure relief valve regularly to ensure it is functioning properly and prevents over-pressurization.

- Monitor Pressure Gauge – Keep an eye on the pressure gauge to ensure the compressor is running within optimal pressure range.

Additional information

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

|---|---|

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-05-18T16:43:13Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet