Current Tools Hydraulic Knockout Set – Reconditioned – Current Tools 154PM

9999 in stock

$1,512.00 Original price was: $1,512.00.$1,059.00Current price is: $1,059.00.

9999 in stock

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

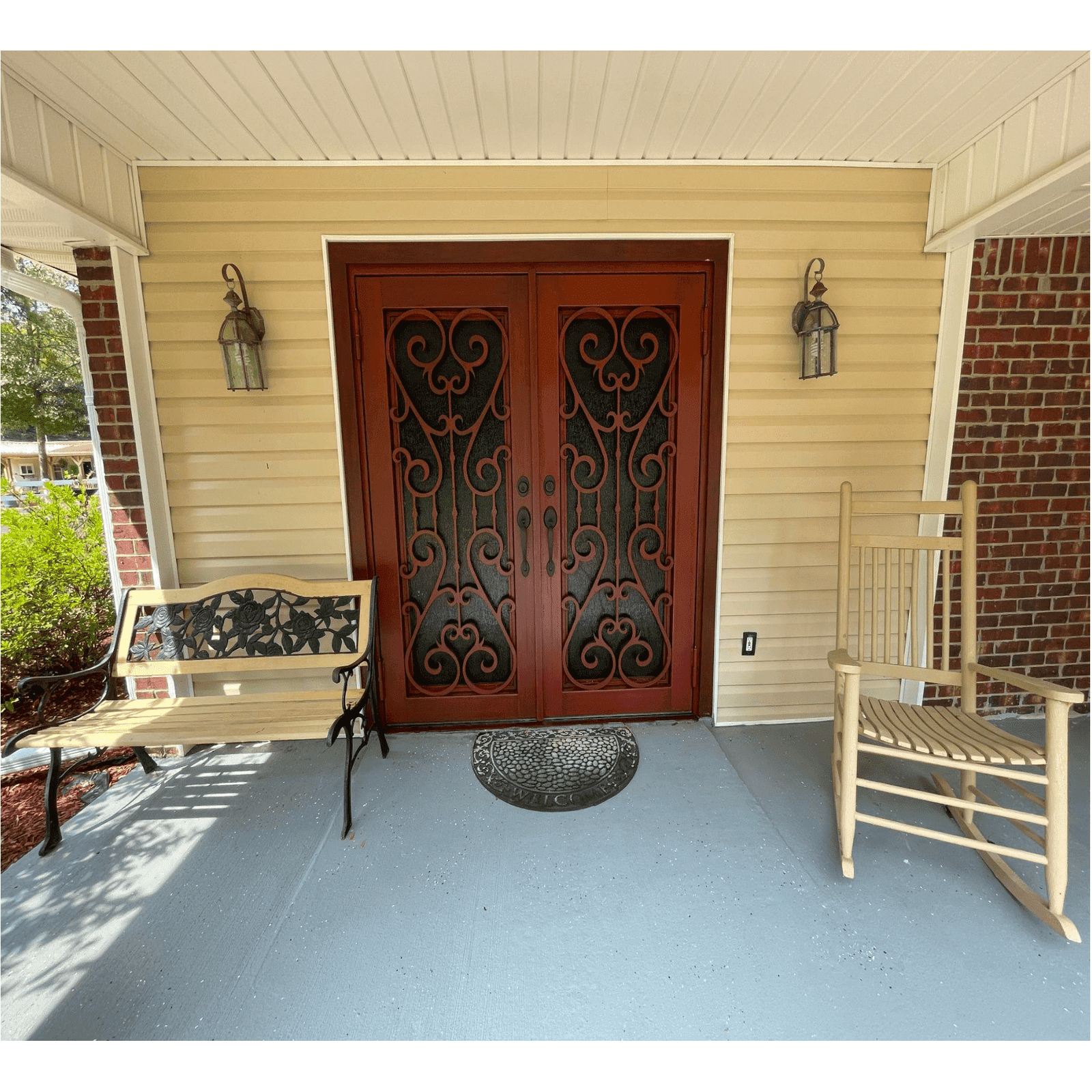

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

Current Tools Hydraulic Knockout Set – Reconditioned – Current Tools 154PM

1 Inch to 4 Inch

Designed to slip slugs into two pieces for easy removal

Designed to punch a max of 10 Gauge (.134″) mild steel

Fast Set-up

Comparable with Greenlee Slug-bluster Models 7306SB and 7310SB

Made in the USA

What our Experts Think

-

Precise Knockouts: The Current Tools 154PM Hydraulic Knockout Set is designed for accurate knockout punching of 1/2″ to 2″ diameter conduit, ensuring clean cuts every time.

-

Reconditioned for Value: Fully restored to like-new condition, delivering reliable performance at a more affordable price.

-

Durable and Robust: Constructed with high-quality materials for long-lasting durability, this set can handle tough industrial environments.

-

Hydraulic Power: With its hydraulic system, it makes knockout punching faster and easier, minimizing manual effort and boosting productivity.

-

Ideal for Professionals: Perfect for electricians and contractors who need a dependable tool for efficient and precise conduit work.

Q&A

Q: What is the Current Tools Hydraulic Knockout Set used for?

A: It is designed for creating precise holes in conduit for electrical installations, covering a range of sizes for versatility.

Q: Is this product reconditioned?

A: Yes, the Current Tools 154PM Hydraulic Knockout Set is reconditioned, providing high-quality performance at a lower cost.

Q: What are the key features?

A: Features include hydraulic power for smooth operation, durable construction, and compatibility with various conduit sizes.

Q: Is this product suitable for professional use?

A: Yes, it is ideal for electricians and contractors who require a reliable tool for efficient and accurate knockout punching.

Q: Why choose a reconditioned model?

A: Reconditioned models offer excellent value, ensuring reliable performance at a reduced price, with full inspection for quality and longevity

Maintenance Tips

-

Inspect for Damage – Regularly check for any damage to the hydraulic components, punches, and dies, including cracks or wear.

-

Keep Clean & Free of Debris – Clean the knockout set after each use to prevent dirt or debris buildup that could affect performance.

-

Lubricate Moving Parts – Apply the recommended lubricant to moving components, such as the hydraulic piston and dies, to maintain smooth operation.

-

Monitor Hydraulic Fluid Levels – Check the hydraulic fluid levels and top up as necessary to ensure consistent pressure and performance.

-

Inspect Punches & Dies – Examine the punches and dies for wear, cracks, or other signs of damage. Replace them as needed to maintain cutting precision.

-

Tighten Fasteners – Ensure that all bolts and fasteners are secure to prevent any loosening during use.

-

Monitor Load Capacity – Always use the knockout set within its rated capacity to avoid damaging the components or causing accidents.

-

Store in a Dry Area – Store the set in a dry, moisture-free environment to prevent rust or corrosion, especially on the hydraulic parts.

-

Check Alignment – Ensure the punches and dies are properly aligned during operation to avoid misalignment and ensure accurate cuts.

-

Follow Manufacturer’s Guidelines – Stick to the manufacturer’s maintenance recommendations and schedules for extended longevity and peak performance.

Additional information

| Weight | 72 kg |

|---|---|

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-05-18T16:17:58Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Canon RF 600mm F11 IS STM – 795096

$799.99 -

Canon RF 70-200mm f4 IS – 1018103

$1,599.00 -

Sale 30%

Current Tools Pipe Bending Shoe – Reconditioned – Current Tools 2-1401

$1,577.00Original price was: $1,577.00.$1,104.00Current price is: $1,104.00. -

Sale 30%

Current Tools Work Station for 1/2in to 1-1/4in. Conduit – Reconditioned – Current Tools 752

$3,070.00Original price was: $3,070.00.$2,149.00Current price is: $2,149.00.

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet