Atlas Copco 15HP, 62.8 CFM, 120 Gallon G11 Rotary Screw Air Compressor 208-230/460V – 8153290864

19998 in stock

$14,207.00 – $14,282.00Price range: $14,207.00 through $14,282.00

authorized dealer, shop your favorite brand.

Expert Support, Dial +1 (888) 851-3898

Limited Supply, grab it before it's gone.

Lowest prices, As low as possible.

All Item are brand New, Never used.

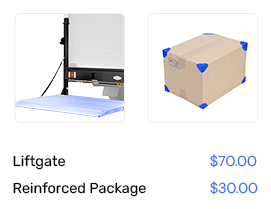

Popular Add-Ons

Recently Viewed Products

PRx Performance Rubber Hex Dumbbells – PXB320

$1.99 – $999.00Price range: $1.99 through $999.00

PRx Performance Crumb Rubber Bumper Plates – PXB310

$49.00 – $549.00Price range: $49.00 through $549.00

PRx Profile Incline Folding Bench -PX623

$799.00

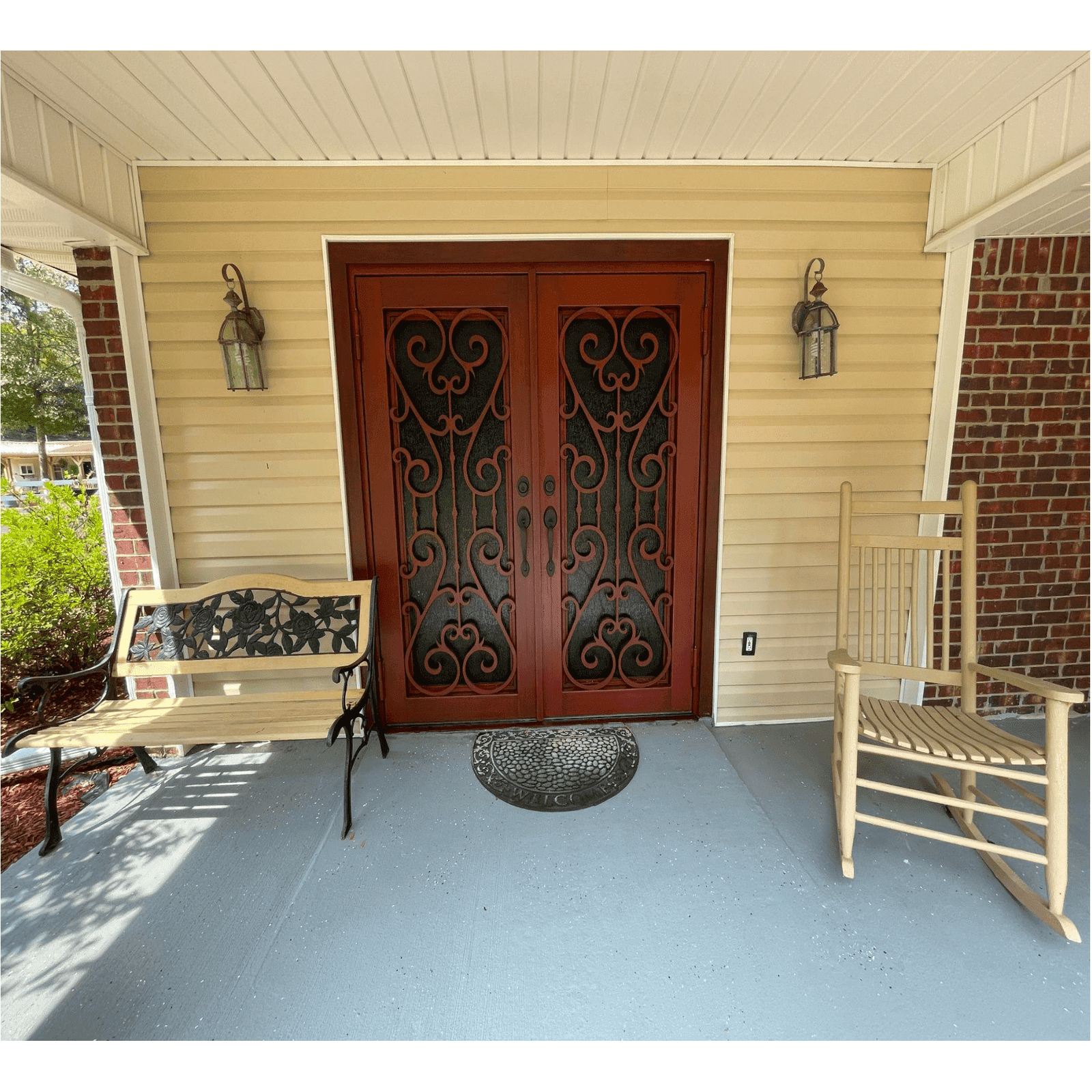

Premier Iron Doors USA Made Custom Iron Entry Door Palladian Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Tuscan Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Premier Iron Doors USA Made Custom Iron Entry Door Orleans Design

$7,473.99 – $7,802.99Price range: $7,473.99 through $7,802.99

Description

Atlas Copco 15HP, 62.8 CFM, 120 Gallon G11 Rotary Screw Air Compressor 208-230/460V – 8153290864

Introducing the G11 – your reliable 11 kW / 15hp workhorse that delivers up to 61.6 cfm of compressed air. Unlike piston compressors, screws offer smooth operation and high-speed performance in a compact design, making it perfect for continuous, workplace, and industrial applications. Choose from floor or tank-mounted options, with four pressure variants (7.5bar, 8.5bar, 10bar, and 13bar) available. With advanced control options and remote monitoring upgrades, the G11 provides peace of mind. It’s also quiet at 66 dB and highly efficient, delivering energy savings of 2-3% compared to other systems. With a 100% duty cycle, the G11 is always ready to provide compressed air when you need it. Elevate your operations today with the G11.

Product Image for Reference Only. Actual Product May Vary.

Specification

| Model | G11-125 FF 208-230/460, 120 Gallon |

|---|---|

| Model Number | 8153290864 |

| Category | Rotary Screw Air Compressor |

| Product Range | G11 |

| Tank Capacity (Gallons) | 120 |

| CFM (Cubic Feet/Minute) | 62.8 |

| HP (Horse Power) | 15 |

| Voltage | 208-230/460 |

| Phase |

What Our Experts Think

- Powerful 15HP Motor – Delivers 62.8 CFM at 150 PSI, ideal for industrial applications with moderate to high air demand.

- Rotary Screw Technology – Offers reliable and continuous airflow with minimal maintenance.

- 120-Gallon Tank – Large air storage reduces cycling and ensures consistent air pressure for heavy-duty tasks.

- Energy-Efficient – Operates on 208-230/460V three-phase power, maximizing energy efficiency.

- Quiet & Durable – Engineered for low noise levels and built to handle continuous-duty operations.

- Versatile & Reliable – Perfect for a range of industrial applications requiring high, sustained airflow.

Q&A

Q: What industries can benefit from this compressor?

A: Ideal for medium to large workshops, manufacturing plants, automotive facilities, and other high-demand industries requiring consistent, high-volume compressed air.

Q: How does the rotary screw design improve efficiency?

A: The rotary screw technology provides smooth, continuous air compression with minimal energy consumption, making it a cost-effective solution for long-term operation.

Q: Does this compressor include an aftercooler?

A: This model does not include an aftercooler, but it can be paired with one to ensure moisture control and improve air quality.

Q: What are the voltage requirements for this compressor?

A: The G11 compressor operates on a 208-230/460V three-phase electrical system for versatile installation.

Q: How often should maintenance be performed?

A: Regular maintenance includes oil changes, filter replacements, and periodic system inspections to maintain optimal performance and extend the compressor’s life.

Q: What is the air tank size and how does it benefit operations?

A: The compressor comes with a 120-gallon air tank, providing ample storage to ensure continuous and efficient airflow even during peak demand periods.

Maintenance Tips

- Check and Change Oil – Monitor oil levels regularly and replace according to the manufacturer’s schedule to ensure smooth operation.

- Inspect and Replace Air Filters – Clean or replace air filters every 2,000–4,000 hours to maintain optimal airflow and air quality.

- Drain Moisture from the Tank – Drain the 120-gallon tank regularly to prevent moisture buildup, rust, and corrosion inside the tank.

- Monitor Belt Tension – Inspect drive belts for wear and adjust or replace as necessary to ensure proper tension and avoid slippage.

- Clean the Aftercooler – Regularly clean the aftercooler to prevent dust and debris buildup, ensuring efficient cooling and performance.

Additional information

| Badge | <div style='display:none' class='jdgm-prev-badge' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <span class='jdgm-prev-badge__stars' data-score='0.00' tabindex='0' aria-label='0.00 stars' role='button'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </span> <span class='jdgm-prev-badge__text'> No reviews </span> </div> |

|---|---|

| Liftgate Service | No, Yes (+$75.00) |

| Widget | <div class='jdgm-rev-widg' data-updated-at='2025-05-18T16:40:22Z' data-average-rating='0.00' data-number-of-reviews='0' data-number-of-questions='0'> <style class='jdgm-temp-hiding-style'>.jdgm-rev-widg{ display: none }</style> <div class='jdgm-rev-widg__header'> <h2 class='jdgm-rev-widg__title'>Customer Reviews</h2> <div class='jdgm-rev-widg__summary'> <div class='jdgm-rev-widg__summary-stars' aria-label='Average rating is 0.00 stars' role='img'> <span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span> </div> <div class='jdgm-rev-widg__summary-text'>Be the first to write a review</div> </div> <a style='display: none' href='#' class='jdgm-write-rev-link' role='button'>Write a review</a> <div class='jdgm-histogram jdgm-temp-hidden'> <div class='jdgm-histogram__row' data-rating='5' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 5 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='4' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 4 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='3' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 3 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='2' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 2 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row' data-rating='1' data-frequency='0' data-percentage='0'> <div class='jdgm-histogram__star' role='button' aria-label="0% (0) reviews with 1 star rating" tabindex='0' ><span class='jdgm-star jdgm–on'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span><span class='jdgm-star jdgm–off'></span></div> <div class='jdgm-histogram__bar'> <div class='jdgm-histogram__bar-content' style='width: 0%;'> </div> </div> <div class='jdgm-histogram__percentage'>0%</div> <div class='jdgm-histogram__frequency'>(0)</div> </div> <div class='jdgm-histogram__row jdgm-histogram__clear-filter' data-rating=null tabindex='0'></div> </div> <div class='jdgm-rev-widg__sort-wrapper'></div> </div> <div class='jdgm-rev-widg__body'> <div class='jdgm-rev-widg__reviews'></div> <div class='jdgm-paginate' data-per-page='5' data-url='https://api.judge.me/reviews/reviews_for_widget' style="display: none;"></div> </div> <div class='jdgm-rev-widg__paginate-spinner-wrapper'> <div class='jdgm-spinner'></div> </div> </div> |

Related products

-

Atlas Copco 7.5HP, 21.2 CFM, 53 Gallon G5 Rotary Screw Air Compressor 230V 1PH – 8152103851

$10,328.00 – $10,403.00Price range: $10,328.00 through $10,403.00 This product has multiple variants. The options may be chosen on the product page -

Atlas Copco 10HP, 36 CFM, 120 Gallon CR Professional Series TEFC/NEMA4 Cast Iron Piston Air Compressor 230V 3PH – 2020041846

$8,310.00 – $8,385.00Price range: $8,310.00 through $8,385.00 This product has multiple variants. The options may be chosen on the product page -

Atlas Copco 10HP, 34.1 CFM, G7 Rotary Screw Air Compressor 208-230/460V – 8152103707

$9,509.00 – $9,584.00Price range: $9,509.00 through $9,584.00 This product has multiple variants. The options may be chosen on the product page -

Sale -7%

Atlas Copco 15HP, 53 CFM, 120 Gallon G11 Rotary Screw Air Compressor w/Aftercooler 208-230/460V -8153294528

$10,697.00 – $10,772.00Price range: $10,697.00 through $10,772.00 This product has multiple variants. The options may be chosen on the product page

Guaranteed Safe Checkout

Free Shipping Across Continental US

Expert Support

Authorized Dealer

Official Brand Product Reseller

Reviews

There are no reviews yet