FIX LENGTH CUTTING MODE

SEQUENTIAL CUTTING MODE

*10 sets of cutting size memory (for sequential cutting mode only)

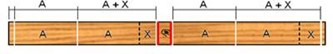

MARKING LINES CUTTING WITH DOUBLE END TRIMMING

MARKING LINES (DEFECTS) CUTTING MODE AND FIXED LENGTH CUTTING MODE

THIS FUNCTION CAN DO THE FOLLOWING JOBS SIMULTANEOUSLY:

-

Defect.

-

Cut the fixed size (A).

-

Cut Finger jointing size without lost (A+X).

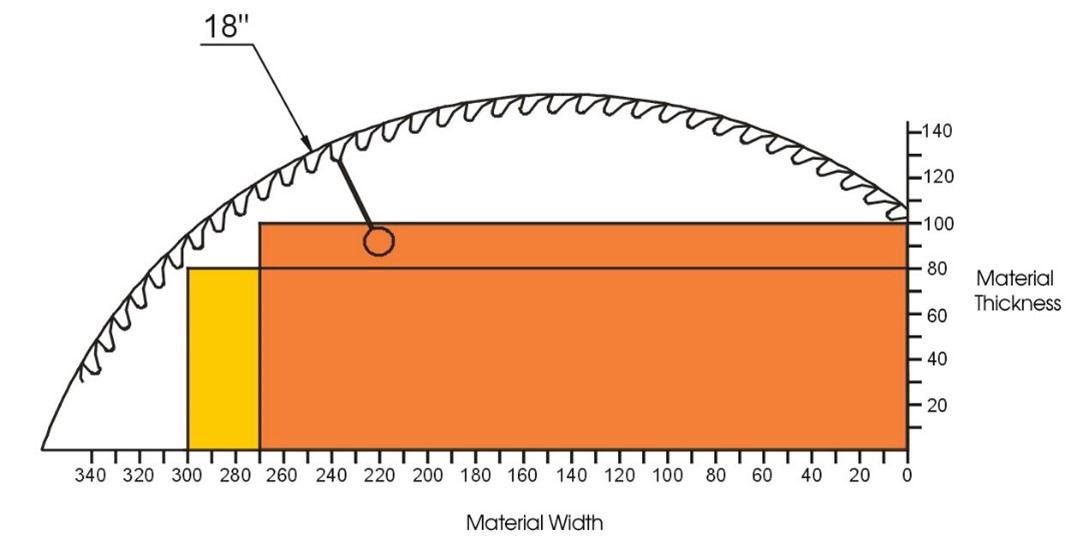

Cutting Range

Max. Cutting Range (WxH) – 11.8” x 2.75” (300x70mm) OR 5.9” x 3.9” (150x100mm) with 18” Blade – Inches = mm x .03937)

Min. Thickness = 0.4” (10mm) (Optional Thin Hold Down Device available to min thickness .078” (2mm)

Options

- Thin Hold Down Device available to min thickness .078″ (2mm)

- Extended infeed table w/ rollers

- Powered infeed conveyor with inspection marking plate

- Lateral infeed chain for automatic loading